Tissue paper is a consumable in life and needs to be purchased after use. The consumption of tissue paper is very large, so you see the huge market potential and development prospects of tissue paper. Therefore, you intend to invest in a tissue paper processing plant. So what about the tissue paper making business? Is it profitable? How to develop a tissue paper manufacturing business? YG tissue paper making machine manufacturer analyzes for you.

In recent years, with the rapid development of society and the economy at home and abroad, the quality of life of residents and their consumption behavior are constantly improving. The market demand for toilet paper continues to be released. As daily necessities that are used every day, hygiene products are consumables. This type of product is low in price and has a high repurchase rate. It is a processing industry with low investment and low risk. In 2020, the size of China's toilet paper market will be about 140 billion. The toilet paper with the largest consumption accounts for about 55%, and the market size is 77 billion yuan. Therefore, the tissue paper making business has a very large market potential.

Nowadays, people pay more and more attention to hygiene and health, and the use of toilet paper has become a necessity in the daily life of the family. Toilet paper does not have a shelf life like other daily necessities. And it can be stored for a long time without squeezing the inventory. Moreover, it has no sales seasons such as off-season and peak season and can be sold all year round. Moreover, the tissue paper manufacturing business does not require a large investment. The purchase of a few machines can be used for a long time. And the raw materials are also very easy to obtain. After the following detailed calculations, process one ton of raw materials, and you can get 500~600 yuan profit. Therefore, the tissue paper making business is definitely profitable.

The costs required to produce tissue paper include raw materials, electricity, labor, machine costs, promotion costs, etc.

Sales profit = sales amount - sales cost.

The following is the specific calculation of the cost and profit of toilet paper processing. Calculated based on cost price and sales price per ton.

| Cost(RMB) | Raw material | Electricity bill | Labor costs | Machine cost | Packing cost | Shipping cost | Loss | Total |

| 6800 | 50 | 200 | 100 | 250 | 250 | 50 | 7700 | |

| Sales Amount(RMB) | 8200 | |||||||

| Profit(RMB) | 500 |

Note: The above is the cost and sales amount calculated according to Chinese prices. And this sales price is the price supplied to the wholesaler. If it is supplied to retailers, the profit will be higher. Please check the cost of manpower, transportation, packaging, raw materials, etc. in your city in detail and the market sales price to calculate the profit.

Tissue paper is always light, soft, and absorbent paper. Tissue paper is obtained after the jumbo roll produced by the paper mill is processed through different steps. There are many types of Tissue paper and its uses are very wide. Common tissue papers include toilet paper, paper towels, facial tissue, napkin, etc.

Toilet Roll

Paper Towel

Facial Tissue

Paper Napkin

| Tissue paper types | Application | Remark |

| Toilet paper | Not only can be used in the bathroom, and toilet, but also can be used to wipe stains | Common forms: toilet paper with core, toilet paper without core, single roll, multi-roll |

| Paper towels | Preserves food, absorbs grease, cleans kitchens, refrigerators, and other cleaning uses. | It is the second largest application in the consumer field, usually two layers, usually with a weight of 20 to 24 g/m2 |

| Facial tissue | Thin texture, soft, good water absorption, smooth, usually used to clean the face | Packing form: soft pump, boxed, cross-folded form |

| napkin | Paper napkins for table use with different patterns, patterns | One to four layers, 1/2, 1/4, 1/6 folding and other folding styles |

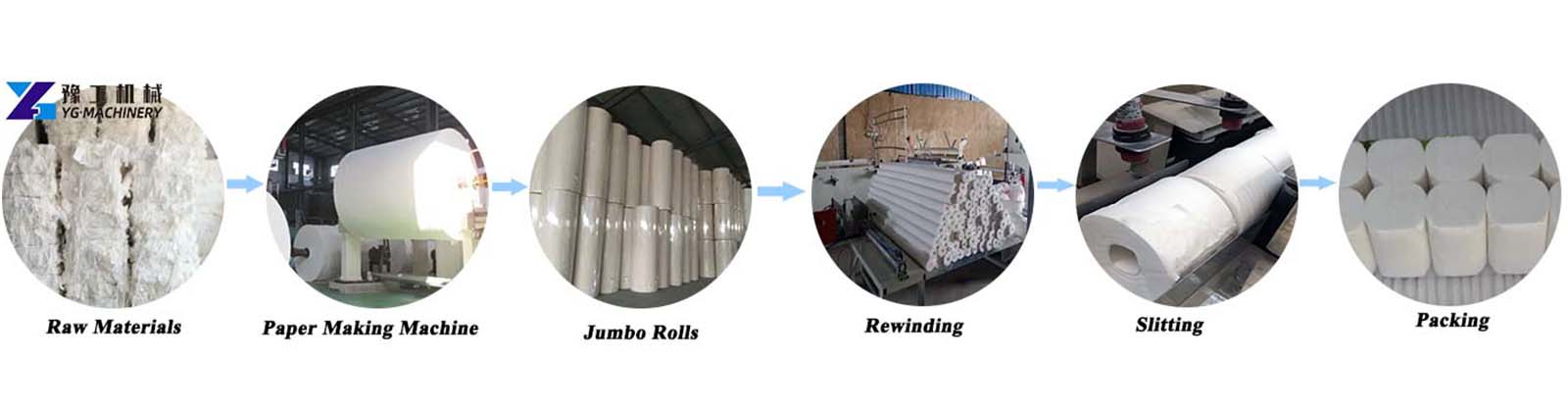

According to the above information, we know that there are many types of tissue paper. Their processing procedures are also slightly different. But generally speaking, the production of most tissue paper has gone through processes such as base paper, cutting, forming, and packaging. The following takes the production of toilet paper as an example to illustrate the tissue paper production process.

If you also want to know the production process of paper towels, paper napkins, and facial tissue, please contact us.

In fact, most of our tissue paper processing factories use base paper purchased from paper mills. Through various machine processing, toilet roll, napkin, facial tissue, etc. are produced. Because the cost of raw materials to large rolls of paper is relatively high. Therefore, you need a fully automatic paper making line. The raw materials used in paper making are mainly cellulosic materials, including wood, bamboo, straw, hemp plants, cotton, waste paper, etc.

Considering that many users are new to the tissue paper production business, the following is a list of related equipment that you need to purchase.

Want to know the detailed quotation of the equipment? Get solution configuration for free? Please leave a message~ We will come as fast as we can.

30min Quick ResponseOnline Message

If you are interested in our machine platforms or have any questions about how they work, then please get in touch using the following contact form.